Kasahara Laboratory, Department of Nuclear Engineering and Management, School of Engineering, The University of Tokyo

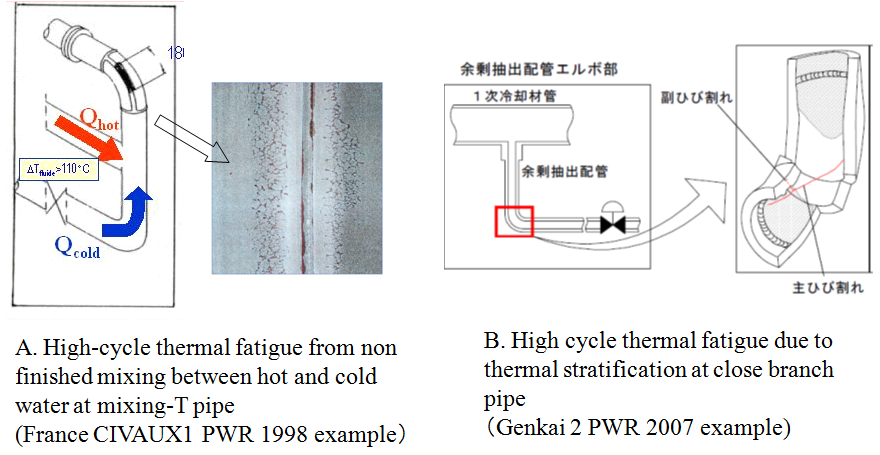

Examples of fatigue failure due to thermal stress, which is caused by fluid temperature fluctuation

Mechanism of fatigue failure due to thermal stress, which causes the fluid temperature fluctuation

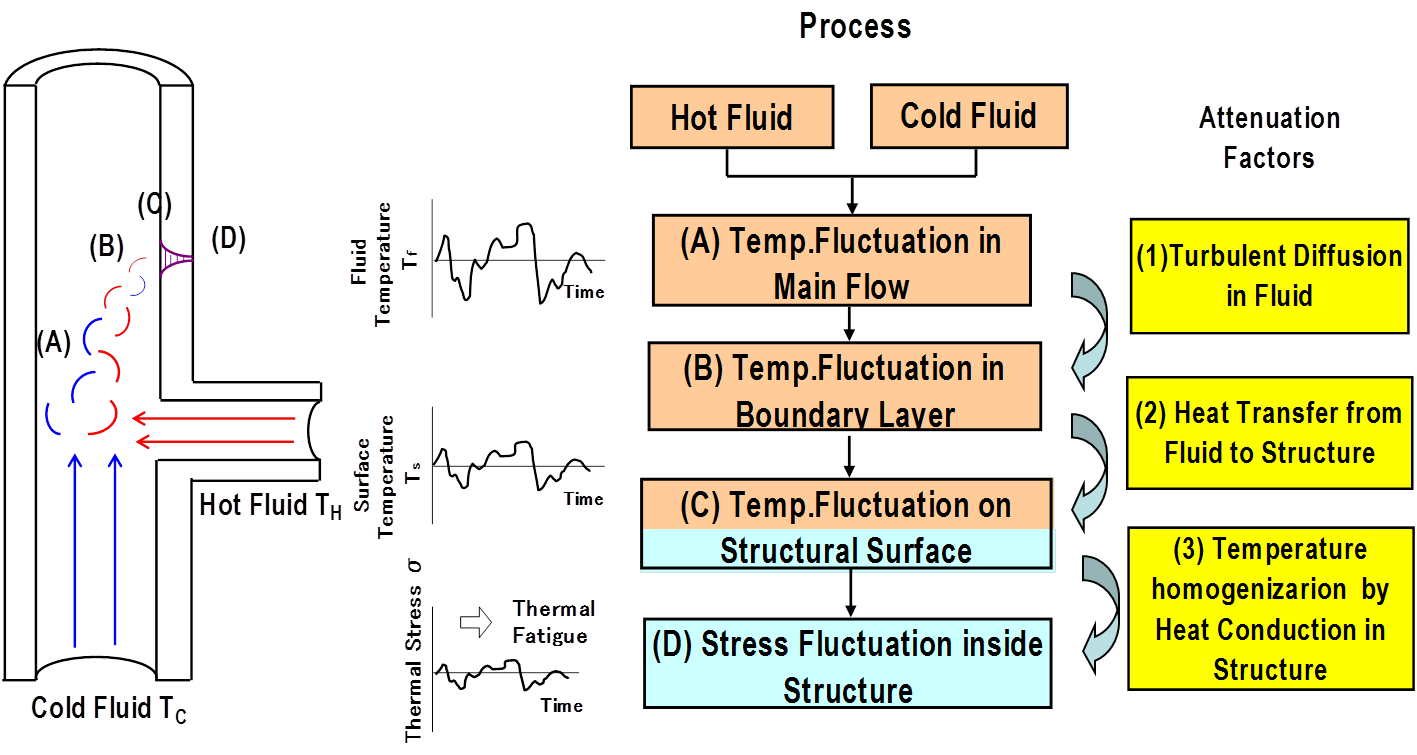

Mechanisms of high-cycle thermal fatigue generated by the fluid temperature fluctuation is composed of elementary processes (1) to (5)

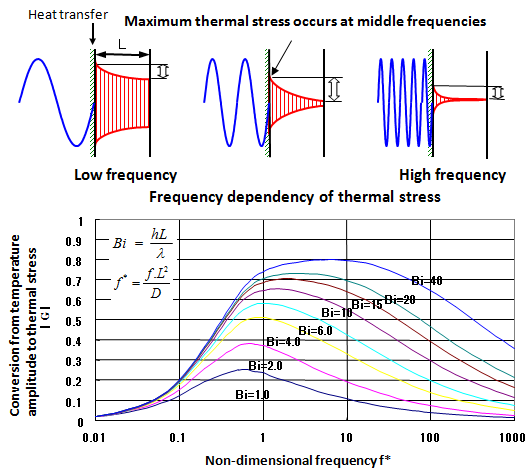

Development of frequency response function of heat stress caused by fluid temperature fluctuation

High frequency temperature distribution is less likely to induce thermal stress due to the structure time delay in the temperature change on its surface when the heat does not transfer from fluid to surface. On the other hand, at low frequency the structure has time to adapt to the temperature change and thermal stress is not likely to appear. However maximum thermal stress appears in intermediate frequency domain where both of these phenomena compete. To understand these mechanisms, frequency analysis is used to clarify the phenomenon.

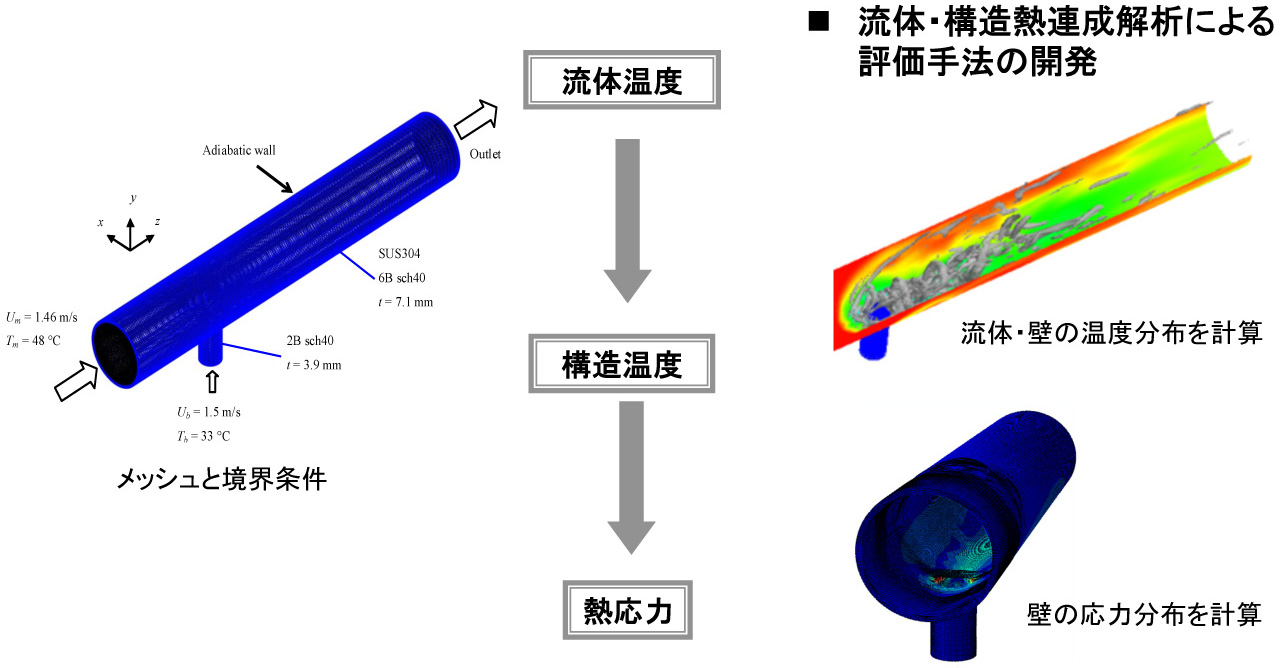

Building a knowledge base for fluid/structure interaction simulation techniques

In order to extend the simulation`s application range to replace necessary test data in JSME guidelines, thermal stress evaluation method that utilizes structural numerical simulation is developed in hopes to provide a basis for evaluation and analysis techniques. Considering the mechanisms below, a thermal-stress-fluid-temperature-fluctuation response function is developed.

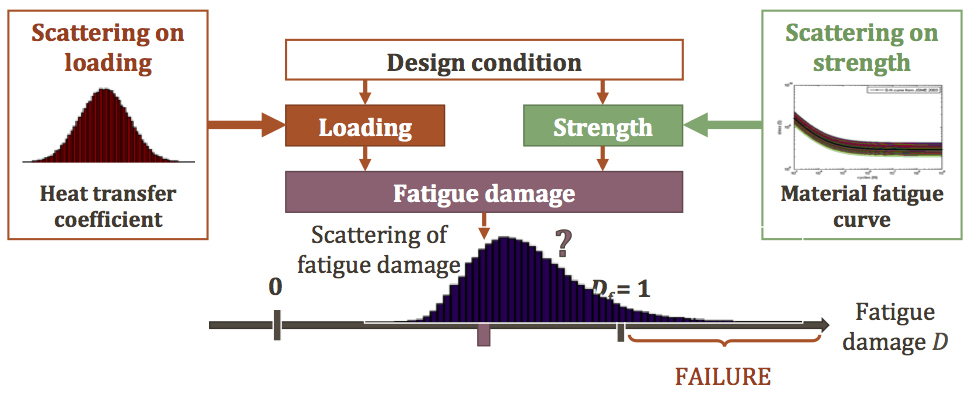

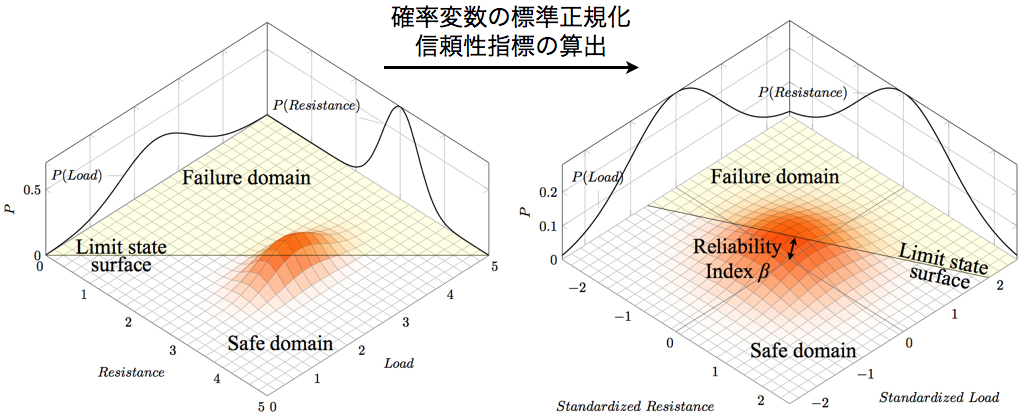

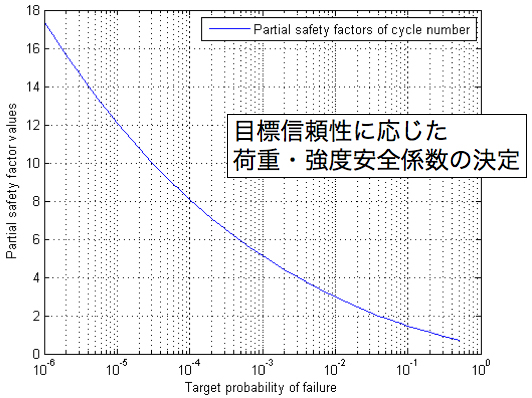

High cycle thermal fatique reliability evaluation of the structure subjected to fluid temperature fluctuation

Quantitative evaluation of structure failure is based on theory of probability considering load and intensity uncertainty and its affect on safety. Further development of a more rational and simple high cycle thermal fatigue evaluation method is based on the results.

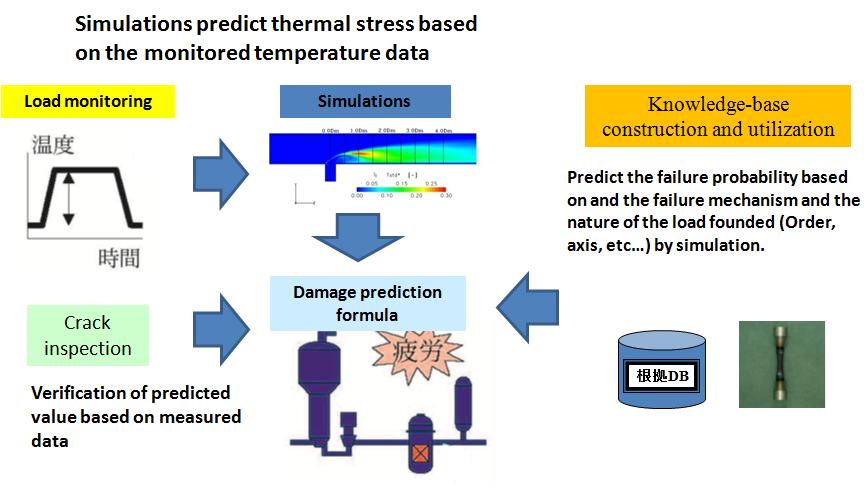

Improvement of degradation prediction method accuracy using knowledge based simulation and monitoring inspection

Because of variations in loading from heat flow phenomena are based on variations in material strength in the plant, structural strength is distributed stochastically. Therefore, we attempt to improve the failure probability prediction accuracy by combining knowledge base, monitoring, inspection, and simulation.

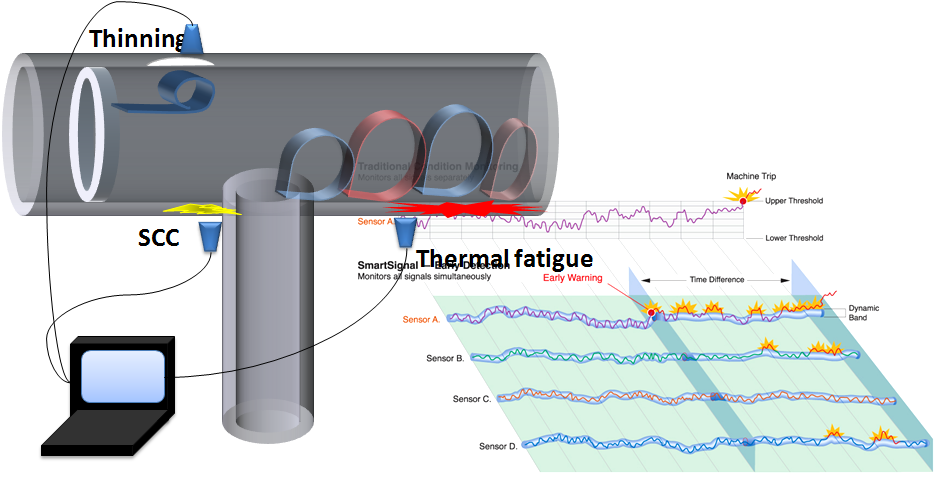

Degradation prediction and defect diagnosis of piping using PCA (principal component analysis) analysis

Thermal fatigue is monitored by installing various sensors on pipes.

Comparison of thermal fatigue data from monitoring and simulations.

PCA analysis of monitoring signal⇒defect diagnosi, (progress estimation)

Comparison of thermal fatigue data from monitoring and simulations.

PCA analysis of monitoring signal⇒defect diagnosi, (progress estimation)